Chemical Process System Lockout / Tagout Procedures Preparation

Process Engineering International, LLC (PROCESS) was contracted to prepare Lockout/Tagout (LOTO) procedures for individual process systems for a multinational materials technology company headquartered in Europe.

To accomplish the draft program development, PROCESS first prepared a project basis document that outlined how the client wanted the Lockout/Tagout process to be developed and presented the ways that process systems would be defined, how LOTO would occur, how the lack of appropriate double block and bleed equipment would be documented, how approval and document control procedures would be executed, program authority, and similar. Each process system was centered around a major piece of equipment such as a tank, scrubber, reactor, etc. Each system contained procedures for multiple pieces of equipment; for example, a tank system typically had procedures developed for the tank itself, associated pumps, line filters, instruments, and any other process equipment associated with that tank that required LOTO procedures.

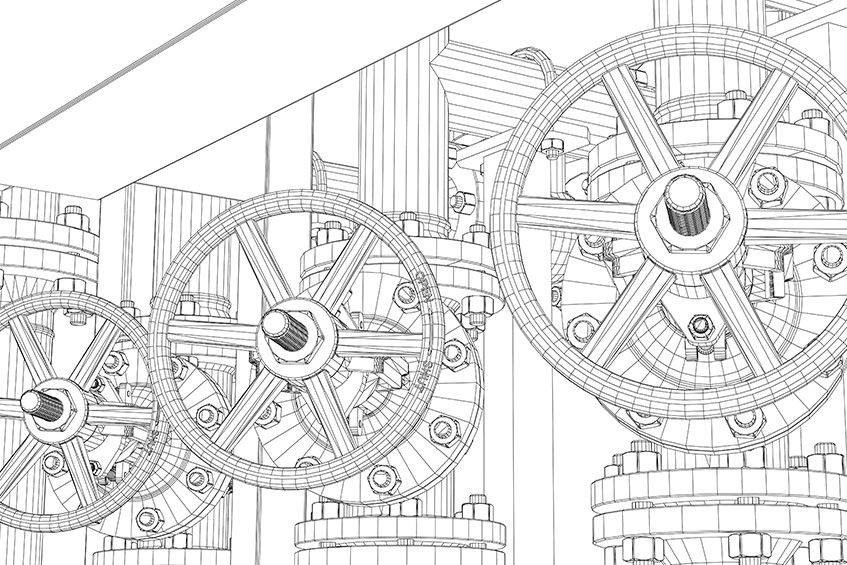

PROCESS then worked with the client to prepare a template for a user-friendly Lockout/Tagout procedure that would be applied to each piece of equipment. The generic procedure outlined how the equipment would be identified, photos that would be included, the use of step-by-step instructions with checklists, site approval procedures, and locations of LOTO points on the site’s Piping and Instrumentation Diagrams (P&IDs).

Once the template was prepared, PROCESS prepared draft procedures with LOTO points highlighted on the P&IDs. A PROCESS project team member then traveled to, and spent significant time at the operating site to view each piece of equipment in the plant, take photographs of the equipment and each Lockout/ Tagout point in both energized and “safe” positions, and outline procedures to accomplish LOTO. Once data was obtained, PROCESS developed the procedures and inserted photos into each one as appropriate. Overall, approximately eighty eight (88) plant systems had LOTO procedures developed for them during the course of this project.