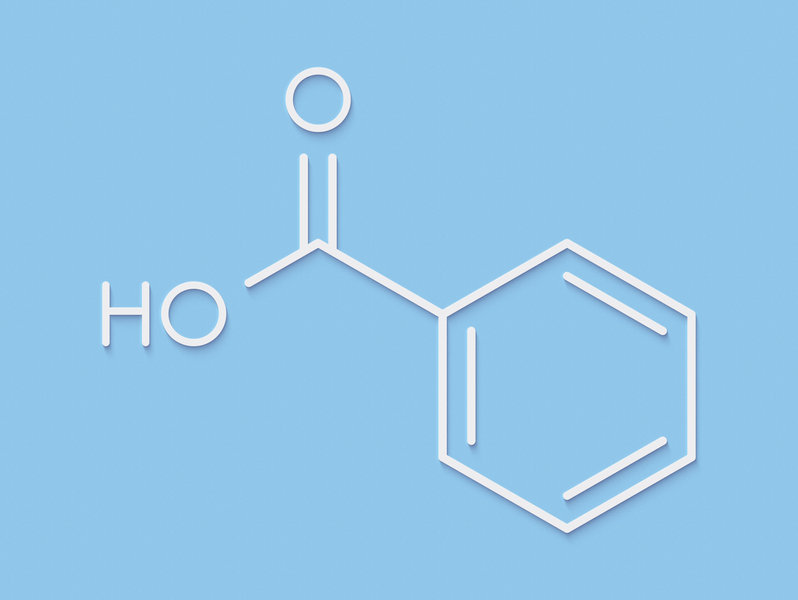

Benzoic Acid Production Facility Process and Quality Improvements Engineering

A privately owned company that operates a benzoic acid production unit in Europe required help to solve several quality issues. The production unit was experiencing quality problems in the form of product purity and color. Process Engineering International, LLC (PROCESS) was contracted to perform an on-site evaluation of the unit, identify potential problems and concerns, and to identify solutions as appropriate while on site.

A Senior Process Engineer from PROCESS visited the facility and quickly identified multiple areas for improvements. These areas included distillation column operational changes, sampling locations, sampling frequency modifications, and material of construction issues.

PROCESS utilized its licensed commercial computer process simulation software to conduct simulations and determine the best operational conditions for generating benzoic acid at the desired quality levels. While on site, PROCESS worked with operations personnel to change the operating parameters for two key continuous distillation columns. Operators were mentored during this process and operating logs were generated to track progress. Product quality was improved to desired levels during the site visit.

During the visit, PROCESS personnel also generated a list of additional improvements to be implemented in the future. This list included changing some materials of construction used in the production unit, suggested safety improvements, suggestions for laboratory upgrades, and other miscellaneous process modifications that would result in safer and more efficient operations.

A report was issued which summarized the results of the study and the simulations.