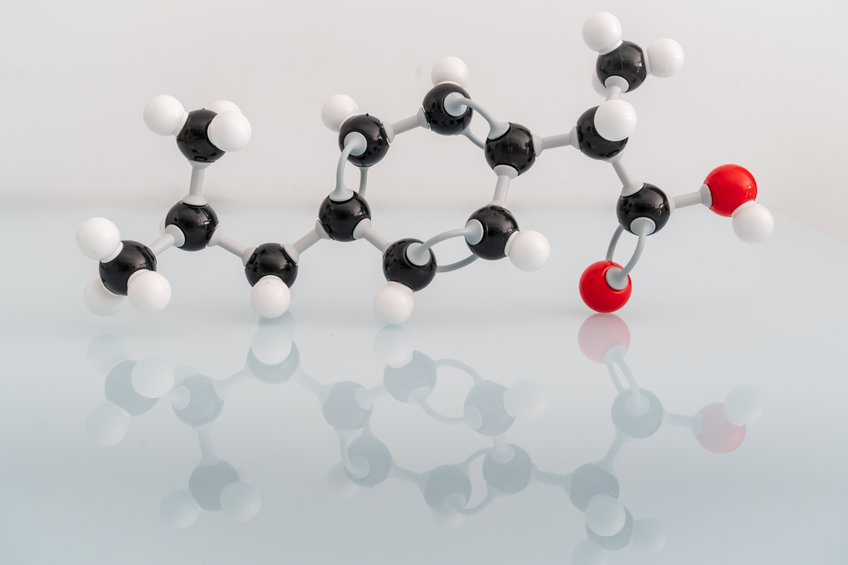

Benzoic Acid Plant Feasibility Study

PROCESS was contracted by an international engineering and construction firm to develop a preliminary process design for a European benzoic acid production facility. This process design was used by the client in preparing a feasibility study for construction of a grassroots plant. Specifically, PROCESS performed the following tasks:

-

Oxidization product compositions determination for two benzoic acid production catalyst systems

-

Product purification and byproduct recovery schemes development based on the reactor effluent composition for each catalyst system

-

Mass and energy balances and development

-

Process Flow Diagrams (PFDs) preparation

-

Equipment lists preparation including preliminary construction materials selection

-

Preliminary plant layout drawings preparation.

Various catalyst systems are available which promote the liquid-phase oxidation of toluene to benzoic acid. Literature data were reviewed and estimates of the reaction product compositions for two systems were determined, each offering certain advantages. The first system considered allowed for higher selectivity toward benzoic acid production as well as valuable side products; however, this catalyst requires the use of higher cost construction materials. The second system allows for the use of lower cost materials; however, impurities generated from the oxidation reaction requires increased purification intensity.

PROCESS used its licensed commercial computer process simulation software to develop mass and energy balances for the reaction and purification systems based on the two potential catalysts. For the first system, purification schemes were developed and included byproduct and catalyst recovery systems. For the second scenario, the purification system was modified to accommodate the lower purity oxidate. The operating conditions determined for each case were shown in the PFDs, providing the client sufficient detail for estimating raw material and energy usages, as well as preliminary capital costs. PROCESS also provided a listing of process and auxiliary plant equipment requirements and developed initial column sizing estimates. Preliminary plant layout drawings were then prepared.